Continued advancement in energy conversion, communication, transportation, and many other critical technologies relies on material innovations, which demand novel synthesis and manufacturing processes for emerging materials and structures. Our research interests are predominantly in the study of structure and property interplay through the interface across different length scales to unlock nanomaterials’ properties at a macroscopic level. To achieve this, we plan to apply theories of material synthesis and assembly and material mechanics characterizations in conjunction with advanced manufacturing techniques (e.g. nanofabrication and additive manufacturing) to create synergy among the nanomaterial properties, structures, and processing. Our research is built on the basis of multi-scale experiments and simulations related to, but not limited to:

- Laser assisted processing and novel metal additive manufacturing techniques

- Fluid mechanics and heat transfer in metal additive manufacturing

- Material characterization and nanomechanics

- Synthesis of carbon nanomaterials and related nanocomposite structures

- Graphene-metal nanocomposites and strengthening & toughening mechanisms

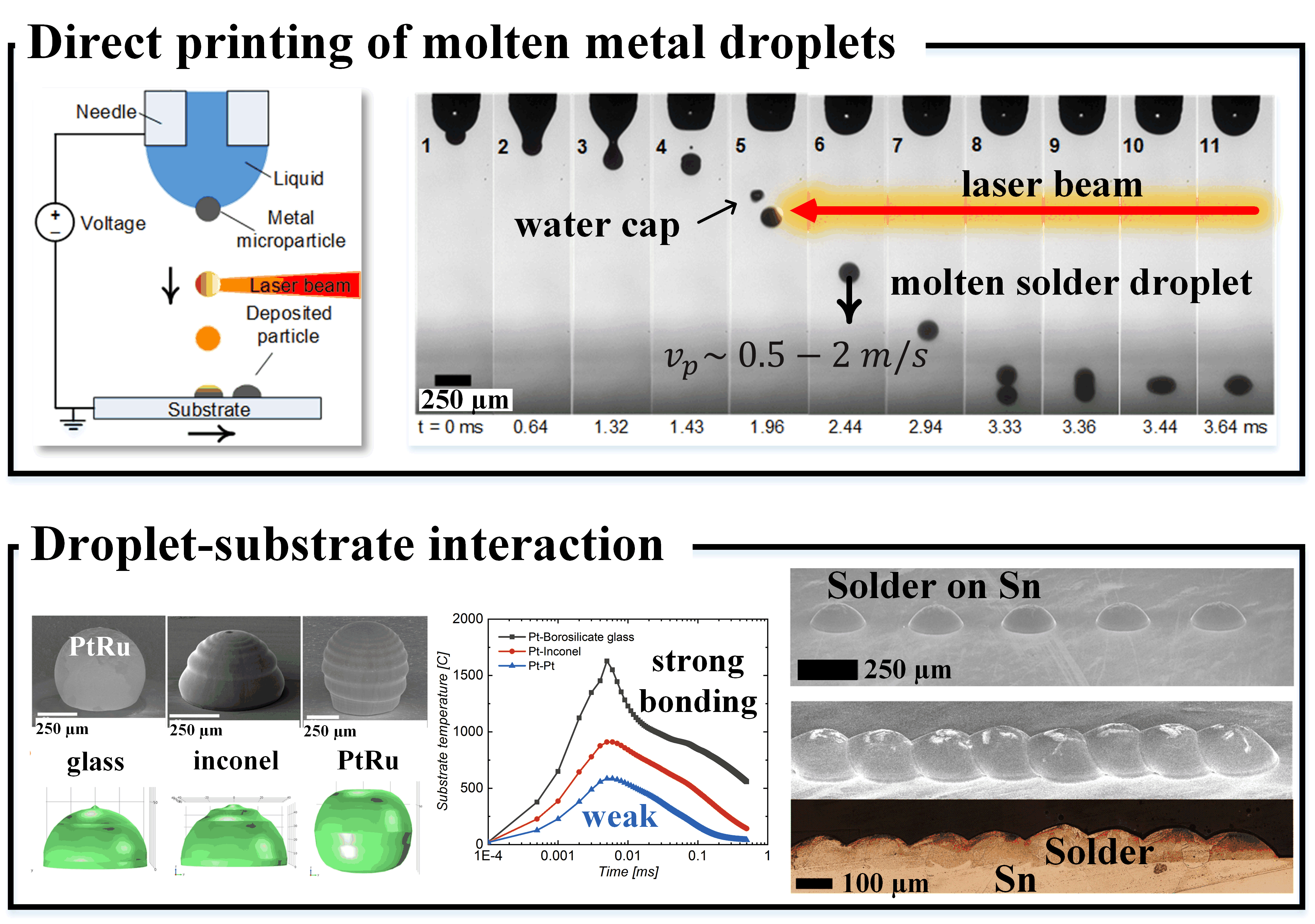

Novel metal additive manufacturing (AM) techniques:

Metal AM is proliferating in the industry. However, it remains challenging to print high-temperature metals, alloy, or highly integrated systems. We plan to utilize the direct metal droplets printing approach to develop new AM techniques that permit high-resolution, multi-metal printing with precise control of microstructures and bulk-like properties. Research focuses on:

- uniform molten metal micro-droplets generation

- hot droplet impingement/spreading/solidification & droplet-substrate interaction

- morphology and microstructure control during metal droplet deposition

- alloy and multi-material additive manufacturing

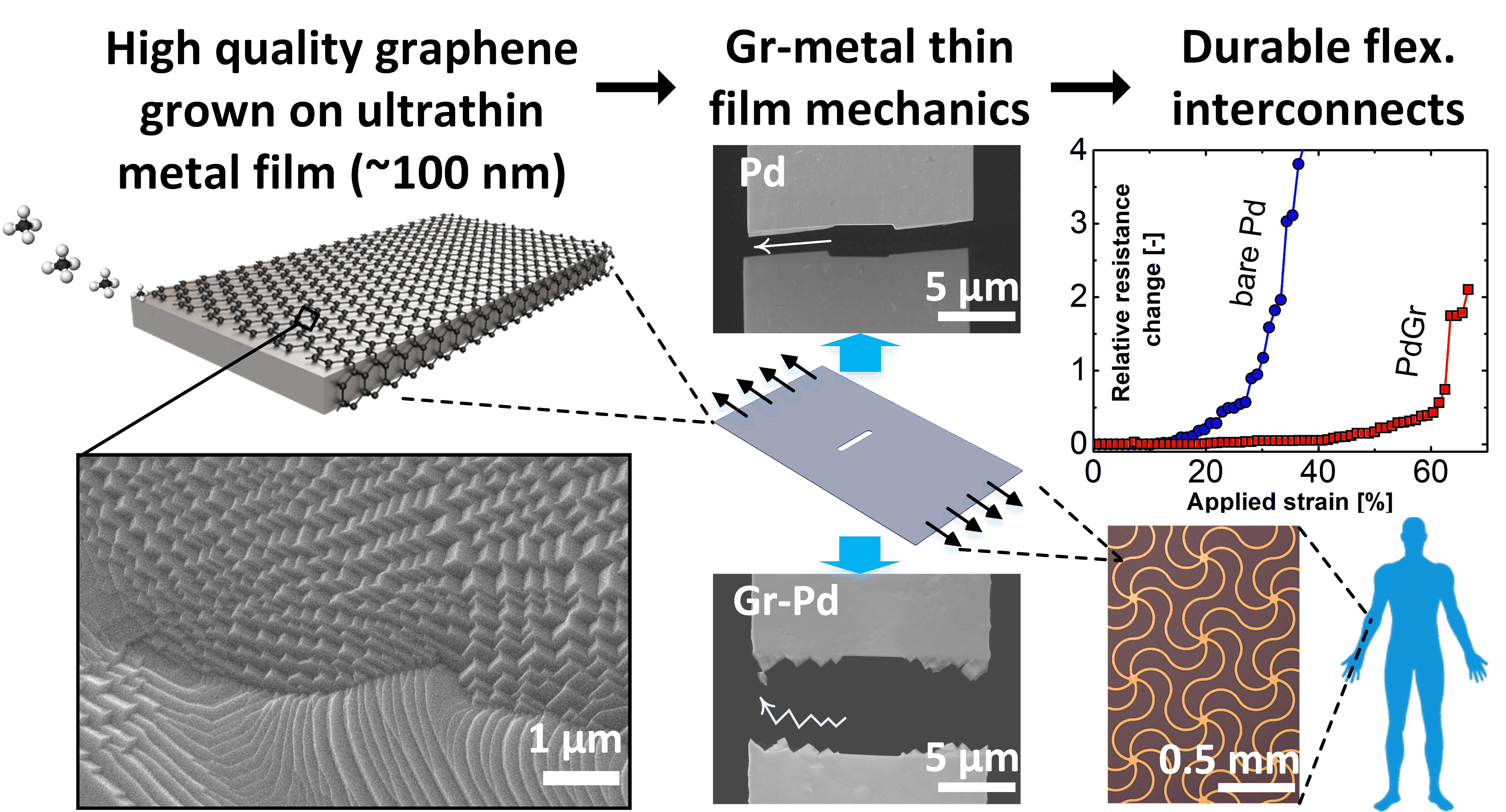

High performance metal matrix nanocomposites:

We use a model system consisting of a metallic nanostructure (e.g. metal nanowires, ultrathin metal films) and a directly-grown monolayer graphene to study interplay between graphene and underlying metal substrate, and related mechanical, conductive, and chemical properties. Research focuses on:

- fabrication of graphene-metal nanocomposites

- mechanical/electrical/chemical characterizations of graphene-metal nanocomposites

- strain/dislocation engineering in graphene-metal nanocomposites

- rational design of monolithic graphene-based composites.

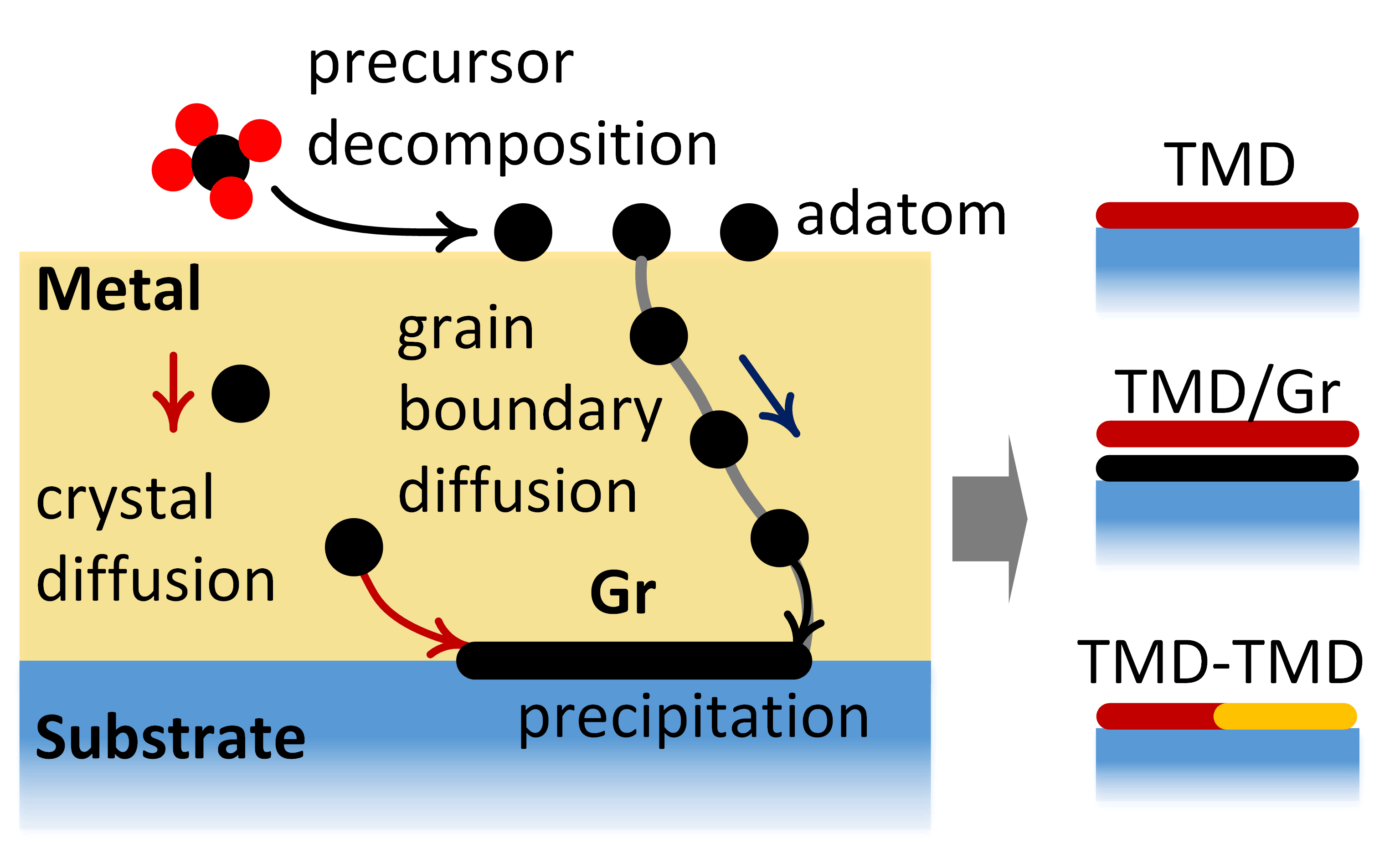

Advanced fabrication of graphene and related layered structures:

Wrinkles invariably form during graphene growth and post-transfer processes and limit the large-scale uniformity of graphene films for electronic applications. Here we study a transfer-free synthesis route of highly-uniform graphene directly on insulating substrates by interfacial carbon precipitation. Research focuses on:

- metal-substrate stability at elevated temperatures

- precipitation control at the metal-substrate interface

- interfacial synthesis of graphene on complex nanostructured interface

- heterogeneous integration by interfacial synthesis, etc.