Study of mass ow distribution between stages in a two-stage pulse tube cryocooler capable of 1.1 W at 4.2 K

Abstract

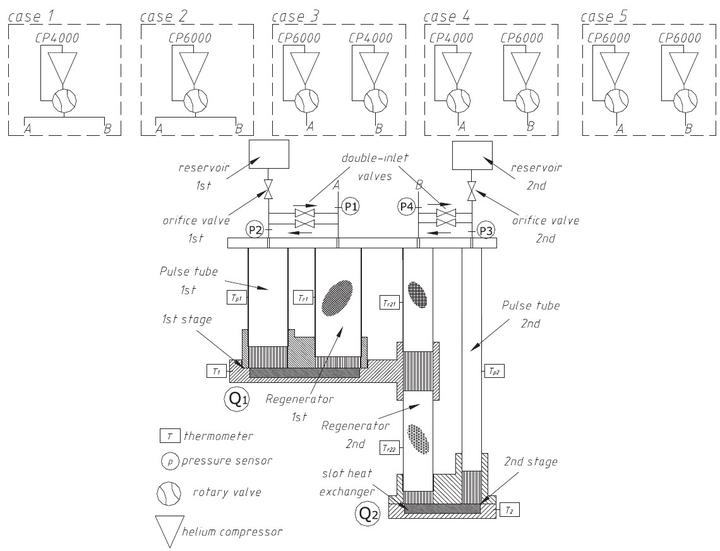

The mass flow distribution among stages is important for design and optimization of multi-stage cryocoolers, which has been seldom investigated due to the complicated mutual interference among stages. The cooling performance’s dependence on operating parameters was investigated in a home-made separate two-stage pulse tube cryocooler (PTC), in which mass flow to each stage can be conveniently adjusted. The numerical study revealed the dependence of cooling performance of the second stage on mass flow rate and precooling temperatures. The experiments with different mass flow rates were performed and results agreed well with simulation. Cooling power of 0.7 W at 4.2 K was obtained with single-compressor and mass flow rate of 3 g s−1 on the second stage; in the two-compressor driving mode, 1.1 W at 4.2 K was achieved with input power of 11.7 kW, which is the largest cooling power ever obtained at liquid helium temperatures in a separate PTC.