Abstract

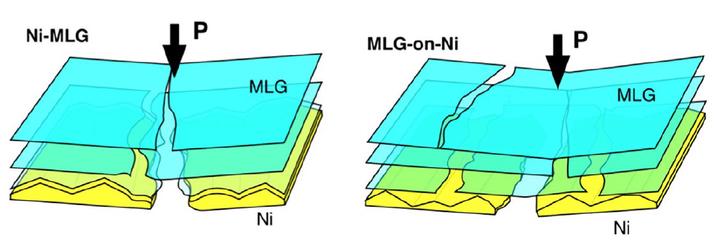

Owing to the superior strength and atomic thickness of graphene, it can in theory reinforce metals beyond the usual rule of mixtures bounds by constraining dislocations motion and strain localization at the grain boundaries. This unusual enhancement relies on the graphene’s ability to conform to and wrap metal grains. This study experimentally probes the limits of this behavior and investigates the role of interface in designing superior graphene composites. Free‐standing nickel–multilayer graphene (Ni–MLG) nanomembranes are fabricated by in situ chemical vapor deposition. Using nanoindentation, elastic modulus (285.16 GPa), maximum stress (2.35 GPa), and toughness (1407.26 Jm−2) are measured, and these values exceed the rule of mixtures bounds. The multi‐frequency atomic force microscopy (AFM) is used to spatially map the elastic properties and topography of the MLG on Ni grain boundaries. This emerging characterization reveals that effective reinforcement is achieved when graphene conforms and bridges the grain texture. Nanoindentation and AFM confirm that these mechanisms are ineffective in non‐conformally attached Ni–MLG composites, which exhibit significantly weaker mechanical behavior. These results guide the design of effective graphene composites by highlighting the importance of nanoscale roughness and interfaces, and clearly demonstrate the superiority of composite processing routes based on in situ graphene synthesis.